Managing a fleet of vehicles is no small task. Whether you’re in charge of a few vans or overseeing a hundred trucks, keeping track of fleet maintenance ensures smooth operations, reduces costs and helps maintain safety.

But with the right approach, tracking and running a smooth fleet maintenance programme doesn’t have to be overwhelming.

In this blog, we’ll break down everything you need to know about fleet maintenance – including how to keep on top of it and keep your vehicles running in good working order.

What is fleet maintenance?

Fleet maintenance involves the regular inspection, servicing and repair of vehicles within a fleet. The main purpose? To ensure they remain safe, efficient and compliant.

Just like health checks for us, they make sure everything is working how it should. Vehicle checks can include anything from oil changes and fluid level checks to tyre replacements and exhaust system diagnostics – and are great for flagging up and identify any issues.

And by staying on top of these simple tasks, you can avoid costly breakdowns, extend vehicle lifespans and ensure the safety of your fleet. It really is that simple.

Read more in our blog: A World Class Approach to Fleet Maintenance

Why is fleet maintenance and tracking important?

Routine maintenance isn’t just about keeping vehicles on the road – it’s about creating a strategy that prevents small issues from becoming costly problems.

Safety first

A regular maintenance programme ensures that vehicles are safe to operate, protecting drivers, cargo and other road users.

Reduced downtime

Proactive tracking helps identify and fix potential issues before they result in breakdowns.

Cost control

Regular maintenance prevents expensive emergency repairs and extends the life of your vehicles, maximising your return on investment.

Compliance

Fleet managers need to meet local and industry regulations for vehicle safety and emissions standards. And keeping detailed maintenance logs helps reduce the risk of fines.

Better planning

With organised tracking, fleet managers can schedule repairs or replacements without disrupting operations.

Fleet maintenance schedules and logs

To effectively manage fleet maintenance, creating a schedule and maintaining accurate logs is essential.

What is a maintenance schedule?

A maintenance schedule is a plan, with alerts at regular intervals, for servicing based on manufacturer recommendations – from mileage to usage. For example, light goods vehicles (LGV) might need an oil change every 5,000 miles, while heavy goods vehicles (HGV) may require more regular checks.

Remember: it’s important to tailor schedules to the needs of your fleet!

What is a maintenance log?

Put simply, it’s a detailed record of each vehicle’s service history. These logs are critical and should include information such as date of service, completed tasks, parts replaced and upcoming maintenance needs. To name just a few!

By keeping thorough logs, you’ll have a clear overview of your fleet’s condition and be able to identify trends, such as recurring issues with specific vehicles.

Top three tips to keep track of fleet maintenance

Getting organised and staying on top of your vehicle maintenance processes can be half the battle. Let’s take a quick look at ways to up your organisational skills, and downplay any mishaps.

1. Use a maintenance checklist

A checklist is a simple – yet powerful – tool for tracking fleet maintenance. It ensures no tasks are overlooked and provides consistency across your fleet. A successful checklist should include:

- Regular oil and filter changes

- Tyre pressure and tread depth checks

- Brake inspections

- Fluid top-ups (coolant, transmission, etc.)

- Battery health tests

- Lights and wiper functionality

By standardising these checks, you can reduce human error and maintain a high standard of vehicle upkeep.

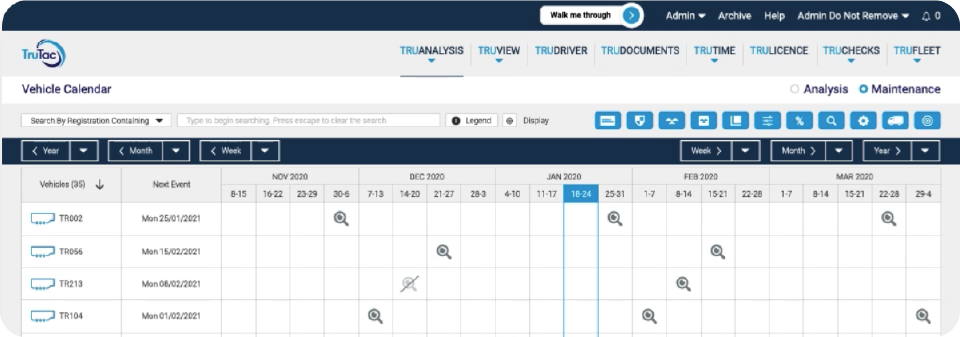

2. Leverage fleet maintenance software

Technology has revolutionised fleet management, making it easier than ever to track maintenance. With the right software at your fingertips, it’s possible to:

- Automate service schedules based on mileage or time intervals

- Receive alerts for upcoming maintenance tasks

- Track repair histories and parts usage

- Monitor fuel efficiency and performance metrics

Software helps centralise your fleet’s maintenance data, enabling quick decision-making and reducing the administrative burden. It’s a no-brainer!

3. Analyse and streamline your current processes

To improve how you keep track of fleet maintenance, start by analysing your current system. Ask yourself:

- Are maintenance schedules being followed consistently?

- Are records accurate and up to date?

- Is communication between drivers and maintenance teams efficient?

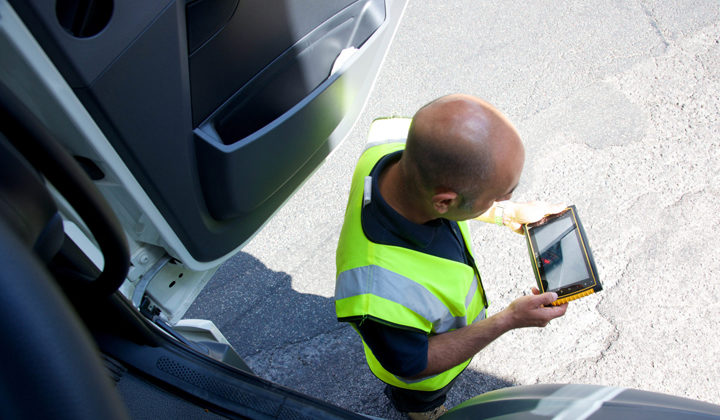

Once you’ve identified any bottlenecks, look for ways to streamline your processes. For example, you could implement a mobile app where drivers can report issues in real-time, eliminating delays in addressing repairs.

For more ideas, read our blog: Five Strategies to Future-Proof Your Fleet

Benefits of proactive fleet maintenance

Taking a proactive approach to fleet maintenance does more than just keep your vehicles running – it has a ripple effect that benefits every aspect of your business.

From improving customer relationships to boosting team productivity, proactive fleet maintenance is a strategic move that supports your long-term goals.

Enhancing customer satisfaction

Timely deliveries and reliable service build trust with clients.

And proactive fleet maintenance ensures your vehicles are in top condition, minimising the risk of breakdowns and delays and allowing your drivers to meet deadlines and provide dependable service.

Boosting productivity

Downtime is one of the biggest productivity killers in fleet operation. And less downtime means more time on the road, generating revenue. By scheduling regular maintenance and addressing potential issues before they escalate, you can keep your fleet running efficiently.

Additionally, a productive fleet also translates into better fuel efficiency. Well-maintained vehicles consume less fuel, reducing costs and improving overall operational efficiency. This means you’re not only saving money but also getting more done in the same amount of time, which ultimately boosts your bottom line.

Improving employee morale

Drivers feel safer and more valued when vehicles are in top condition.

A fleet that’s in excellent condition sends a strong message to your team: you care about their safety and value their contributions. Drivers are more likely to feel confident and secure when operating vehicles they can trust, which leads to higher job satisfaction and better performance.

Moreover, when maintenance is handled proactively, drivers spend less time waiting for repairs or dealing with last-minute vehicle swaps.

By investing in a proactive maintenance strategy, you’re not only safeguarding your fleet but also driving business success. It’s a win-win for everyone involved – from your customers to your employees and your bottom line.