Added compliance, with no additional hardware

It’s our pleasure to share news of our new OEM fleet API integration with GAH Transport Refrigeration, helping fleets maintain continuous temperature compliance across temperature-sensitive operations.

The integration enables operators to meet strict temperature compliance requirements with greater confidence, ensuring goods arrive in the right condition and with ease.

For operators transporting food, pharmaceuticals and other temperature-critical goods, maintaining compliance isn’t just about monitoring, it’s about being able to act quickly if conditions change.

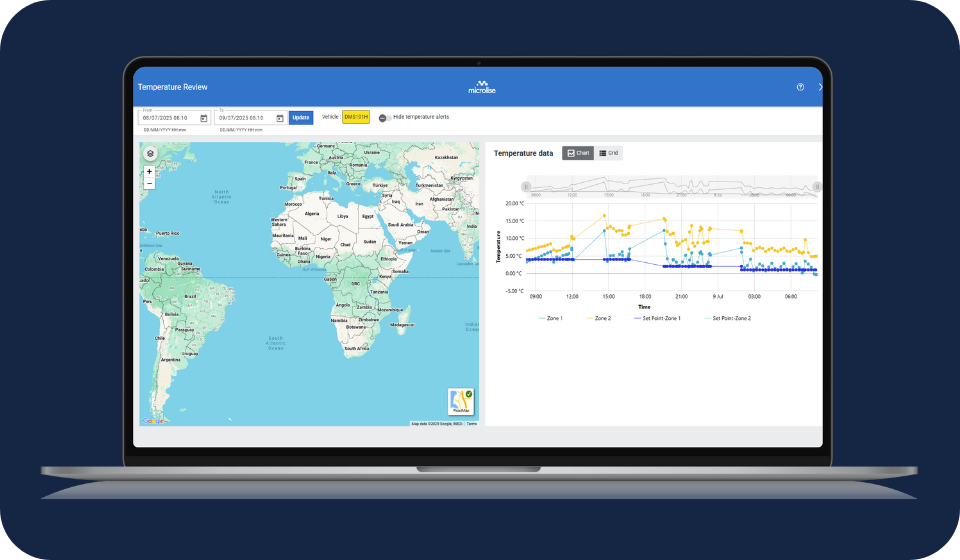

With our new integration, temperature readings from GAH-installed refrigeration units can be transmitted directly into our platform, removing the need for additional probes or bespoke installations.

It also means transport managers can receive alerts if temperatures increase or decrease outside expected thresholds, allowing issues to be resolved before goods are compromised. Door opening events are also monitored, helping teams understand their impact on load temperature and integrity.

Designed for global, mixed fleets

For operators running mixed fleets, this approach provides a simpler, more scalable way to manage temperature compliance across different vehicle types and configurations.

Our Product Director, Stephen Watson, said: “This integration marks the first step in a truly global transformation. No longer do engineers around the world need to install bespoke solutions tied to specific vehicle manufacturers. Instead, we can deliver seamless, manufacturer-agnostic integrations that enable temperature-controlled deliveries to begin immediately, wherever they are and whatever they drive.

“When goods like pharmaceuticals arrive compromised, they’re rendered unusable, which results in significant financial loss. Our solution eliminates that risk by continuously recording temperatures throughout the journey, providing verified compliance with critical standards such as the European EN12830 directive.”

Jon Hill, Applications Manager at GAH, shares the same focus on simplifying compliance for operators. He said, “This integration with Microlise represents a significant milestone in our mission to simplify temperature compliance for our customers.

“By delivering real-time refrigeration data seamlessly into the Microlise platform, we’re removing complexity and cost, while giving operators the visibility and confidence they need to protect temperature-sensitive loads every mile of the journey.”

What this means for customers

This integration is another step in our wider approach to making compliance simpler, more connected and easier to manage at scale. By working directly with partners like GAH, we’re helping operators reduce complexity while maintaining confidence in every temperature-controlled delivery.

If you’d like to see if this new integration could benefit your temperature-controlled operation, get in touch.