Whether you’re delivering your goods to depots in the same organisation or carrying out haulage work for multiple contracts, when you’re running a fleet of vehicles, it’s important to have a plan in place. However – even the best-laid plan can unravel at an astonishing rate – and by the end of the day, what actually happened can look very different to what was planned.

It is important to learn from operational changes to a plan – to push for constant improvement. Industry wisdom usually involves adopting a Plan / Do / Review approach – that is plan what you’re going to do, execute it, then look at any variance (for example jobs out of sequence, deliveries removed from the original plan, unplanned stops, etc.) and at where potential improvements can be made. This approach is one that most people are familiar with and for many years, Microlise has offered a range of transport tools to underpin it.

Planning

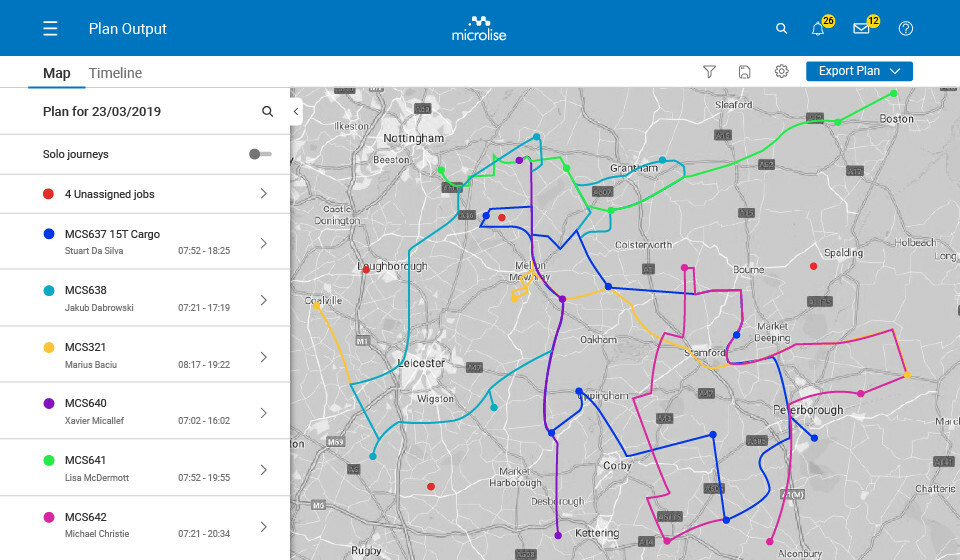

Regardless of how you do it, a plan is always critical. Small fleets may choose to plan manually, larger fleets may use a route planning and optimisation tool… or vice versa. The issue to consider is the time planning takes, particularly if you often need to incorporate last minute jobs, as well as the accuracy of those plans and how efficient they are.

Pooling the jobs to be done and their locations, marrying them up to available resources such as drivers, tractors and trailers, working out the combination of capacity, vehicle type and an efficient route is never an easy task… but these are important elements to consider.

The Microlise Planning & Optimisation tool is designed to do this – quickly and accurately – with minimum manual intervention. If a late job needs to be incorporated, simply add it and re-spin. Job details can be manually imported or imported via integration with your job management software and coupled up with available resources. Once the information passes through the algorithm, a plan of optimum routes is output ready for export to CSV or for one-click feed into our Schedule Execution Board.

Execution

Regardless of how you reach this point, you’ll now have a plan that needs to be implemented. Once your vehicles are on the move, how do you monitor the progress of your deliveries – the location of your vehicles, their arrival times and the sequence in which this is all being executed or the routes taken?

It’s safe to say that most operations now use telematics to track vehicles. Some integrate with planning tools, some have the ability to set geofences to inform users when a vehicle is approaching a destination. Some systems also use these geofences to offer an idea of ETA. However, gathering this information doesn’t always lend itself to monitoring the execution of planned work.

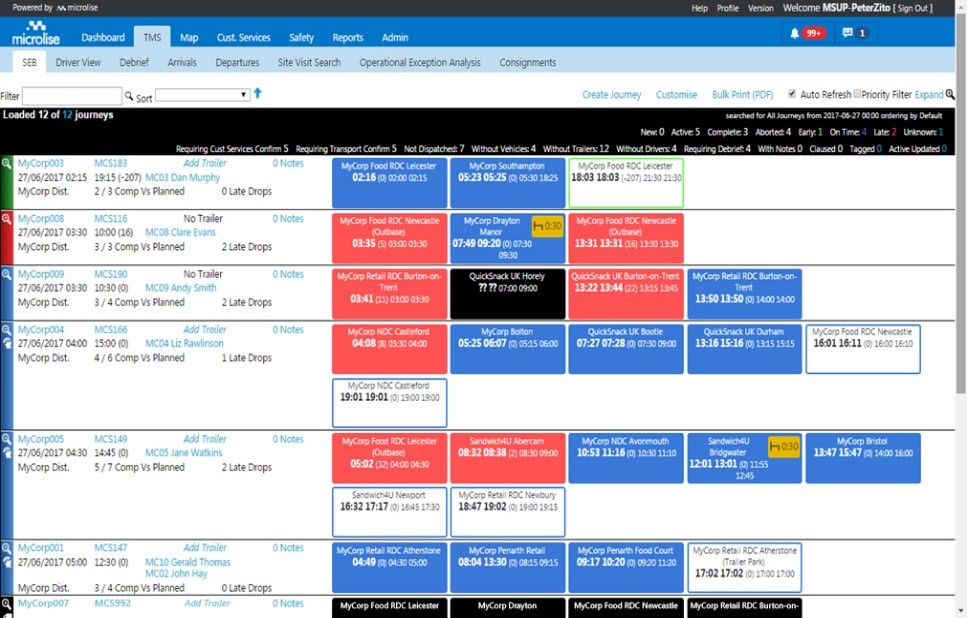

Microlise offers all of the above telematics functionality and more within our standard products. Where the Microlise Journey Management product differs and is unique is in its offering when executing the plan. The Schedule Execution Board (SEB) within Journey Management offers a view of the plan as it is being executed.

The SEB gathers information around the delivery from the plan and compiles it into an easy-to-use timeline with all journeys laid out job by job, and by resource.

Resource information can be found on the left-hand side of the screen with the timeline running from left to right. At the beginning of the day or shift, jobs will be marked with a blue outline signifying they’re not complete but are on-time. As drivers begin their journeys, these outlines will change colour to reflect their status starting with the ETA of the first job and the knock on effect to other jobs on route. Any journeys running late or early will be highlighted within the filter options at the top right of the screen. Perhaps one of your drivers has called in sick or a vehicle has failed its safety check – situations like these have an effect on your timeline but can be dealt with swiftly within Journey Management.

As the day unfolds, each completed job changes to a solid colour showing whether the job was on-time, late, early or missed. Users get a clear idea of the routes that are problematical whilst the routes that are running according to plan can be left to run their course.

Where problems occur, simply knowing in advance provides users with options. Customers can be contacted and notified of issues, agreed timeslots rearranged where possible and fed into the SEB for earlier or later execution and drivers can be notified of any changes via their in-cab terminals. The information from drivers also flows into the SEB with tacho mode information made available on the timeline.

Within the SEB, simply clicking on a job allows users to drill down to further site or visit information showing details on arrival and departure times, turnaround times, the route taken, seal status, planned / actual temperatures, site and contact information and where applicable, consignment and ePOD information.

In essence, any and all information regarding the plan is played out in within the Schedule Execution Board. But as things don’t always go to plan, it is important to examine where execution can be improved.

Post Execution Analysis

Although often overlooked – due to a lack of tools provided by many telematics providers or because time-poor planners underestimate the value of this information – the importance of post-execution analysis should not be underestimated.

Having a plan in place outlining the optimum sequence for jobs and their associated recommended routes is pointless if it is not adhered to but a driver’s local knowledge and years of experience can also be useful and can be factored in, assuming that is doesn’t conflict with company KPIs.

Journey Debrief

The Microlise Journey Debrief function within Journey Management allows managers to get an overview of route adherence along with a host of other information about what happened on route.

Drivers who may have infringed journey requirements are flagged for debrief. A debrief report can be generated for flagged drivers including information around route adherence, schedule and sequence adherence, unscheduled stops and planned distance vs actual distance travelled.

Drivers are invited to a debrief meeting where the exceptions generated in the Journey Debrief report are discussed. At the meeting, drivers have an opportunity to explain the issues involved and provide feedback on their experience, while managers have an opportunity to reinforce the importance of compliance if appropriate, and the reasoning behind it from a company perspective.

Plan vs Actual (PvA) Reports

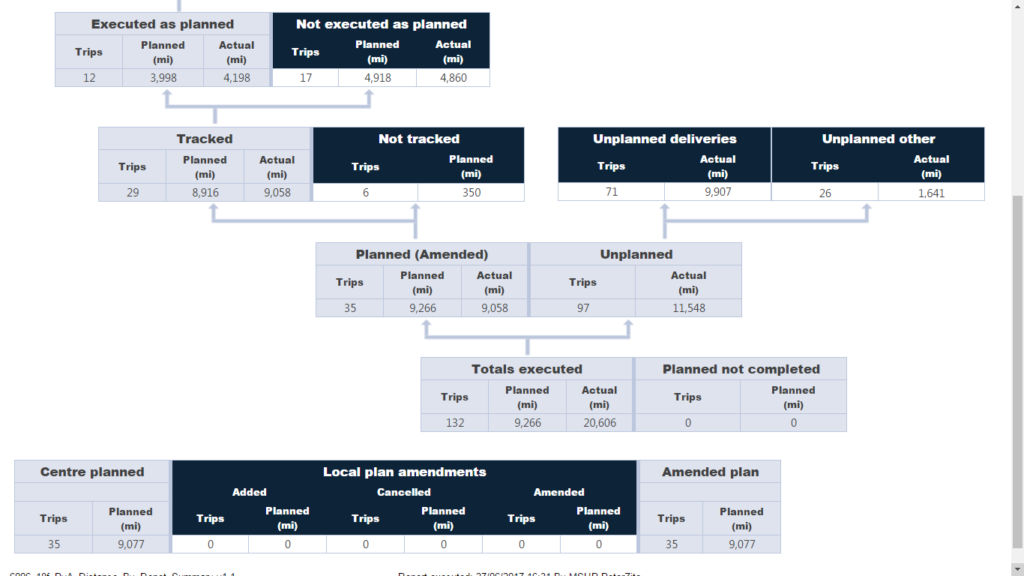

The PvA Report provides a focus for unplanned jobs. It’s always worth considering jobs that were not in the plan to begin with, especially if they are regularly added after a plan has been finalised. It enables questions to be asked – Why are they not in the plan? How do these jobs impact the work in the plan? – and highlights subsequent improvements that could be made.

PvA reports can be run by depot, by legs, by driver, by team lead or as a consolidated PvA. The report highlights performance of the fleet against what was planned. Information includes more / less miles driven and whether it was within tolerance, if the trips were executed as planned or not, whether they were tracked, any unplanned or amended deliveries along with an overview. It also provides the ability to drill down into exceptions for more information.

This report provides managers with an overview of how the operation is performing against plan within a given timeframe and an indication as to where improvements can be made.

Focused Reports

Microlise also provides a suite of reports geared towards more focussed KPIs. When a problem has been identified, managers may wish to target improvements in these specific areas. Reports include turnaround time, plan on time, delivery performance, site / depot geofence delivery window accuracy and more.